ALMALLOY® - CE: Low CTE / Matching CTE Aluminum Alloys The coefficient of thermal extension (CTE) of ADAMCO CE Alloys can be tuned to any value between <7 and 20 ppm/°K The ADAMCO Low CTE Alloys are three to six times lighter than conventional packaging and

baseplate materials used in RF and microwave products like Kovar®,

copper-molybdenum, and copper-tungsten. The standard dimension of our ADAMCO CE Alloys plates are 0.5 X 10 X 10 inches. Larger sizes can be manufactured on request. ADAMCO CE Alloys have a much

better thermal conductivity compared to Kovar®, making them ideal

for high electrical power applications. In comparison to AlSiC, ADAMCO CE

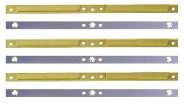

Alloys can be easily machined, plated, and coated. ADAMCO CE Alloys are the optimum choice for thermal expansion matching and light weight applications. ADAMCO CE Alloys are also used for guide-bars of PCBs in aircraft and in other computer products. On one side of the guide-bars particular areas are gold plated providing an optimum fit to the corresponding copper-clad areas on the PCBs where they are soldered to. The other side of the guide-bars is hard nickel plated for good wear resistance when the boards are slid into racks and fastened down. Other typical applications include for instance solid state power amplifiers (SSPAs), optical multiplexers, isolators, coulpers, microwave housings, optoelectronic housings, microprocessor lids, flip chip lids, heat sinks, power substrates, insulated-gate bipolar transistor (IGBT) baseplates, electrical power modules, high voltage modules, DC/DC converters, uninterruptible power supplies (UPS), coolers in hybrid electric vehicles (i.e. pin fin coolers), etc.

|